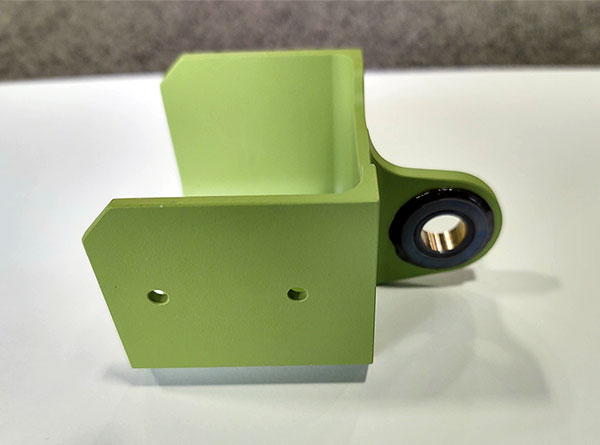

Bushing Installation

One of the most common yet complex processes of aircraft manufacturing and repair is bushing installations. Installing a shrink-fit bushing to tolerance requires a highly skilled team with the tools, techniques and training for consistent perfection and compliance with standards. With 25 years in the business, DABS specializes in precision bushing installation, reaming and honing to the tightest tolerances. DABS also offers bushing and bearing removal services and reinstalls.

For components that require ultimate precision and sizing, DABS employs specialty honing and reaming processes. When surface finish tolerance requirements are extremely tight and simple grinding methods will not suffice, we have the ability to refine the surface finish and size of a component. DABS trained experts in honing and reaming use proprietary process, installation techniques and custom tooling to take on the most complex large and small jobs. From massive rocket engines to small satellites components, bushing and bearing installations are all within DABS’s wheelhouse of expertise.

Honing and Reaming Clarified

Honing is a finishing process used to improve the geometry of a part, readjust the alignment of features such as holes or bores, and produce a finer surface finish. In the honing process, a small, bonded, abrasive stone or super-abrasive stick is rotated over the surface of a part over a controlled path. The honing stones are built with an abrasive grain held together with adhesive. Honing is a high-precision process and is used to improve certain form characteristics such as cylindricity, surface finish, or sphericity.

Reaming is a finishing operation that is performed with multi-edge tools which provide high-precision holes. At a high penetration rate and small depth of cuts, a superb hole quality, close dimensional tolerance and high surface finish are achieved. The operation is performed with the help of reamers which are round cutting tools that enlarge the size of existing holes. Reaming should not be considered only as the correction of location and alignment of holes. The primary purpose of the operation is fine tuning the diameter of the holes.

sales@dabsmfg.com

sales@dabsmfg.com